Hot Sale 1-2ton/h Laundry Bar Soap Production Line In Africa https://www.detergentandsoapmachine.com/products-2-72-p.html

For more details, pls directly contact with Jenny,

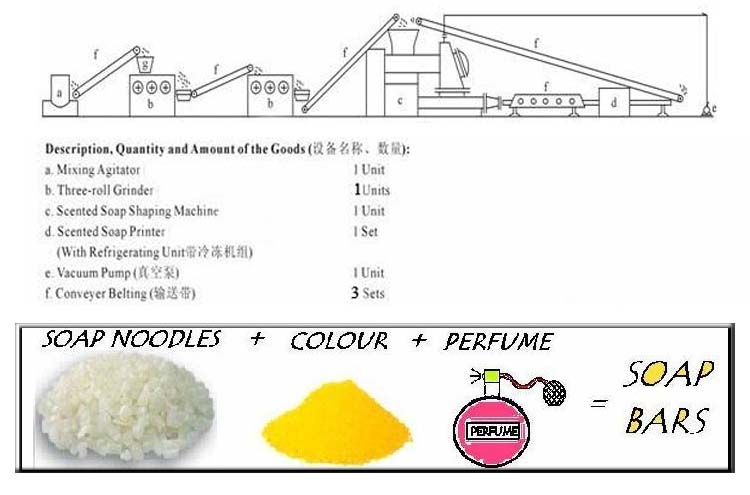

Tel/Whatsapp/Wechat /Telegram: 0086 156 1765 1038,Layout of Soap Production Finishing Line:

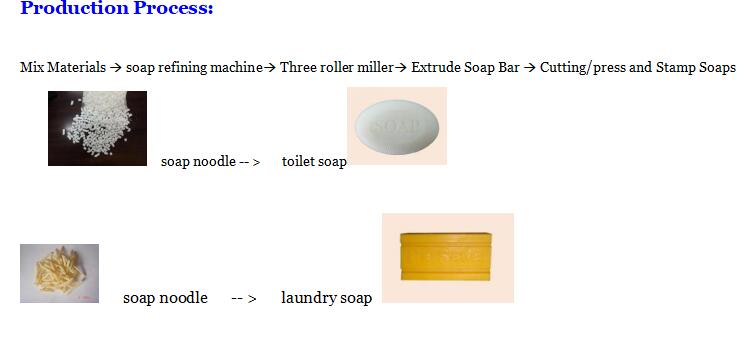

Production flow photos of Soap Production Finishing Line:

Introduction of Soap Production Finishing Line

1. This soap production line take soap noodles(soap bar) as raw materials.

2. The production starts with mixing soap noodles/stripes,perfume pigment,essence and,etc.

2. Then the mixed soap noodles enters in the three roller mill by conveyor belt, where soap thin sheets

are made.

3. The soap thin sheet then converted into desired long strip soap by the vacuum twin screws plodder machine.

4. Then the long strip soap are cut into the soap bars required size and shape by cutting machine or toilet soap stamper machine

5. Finally, the soap bars gets packed by packing machine if needed.

6. Soap bars can be made 15g,20g,30g,60g,120g,200g,260g,500g,800g,1000g,and so on

Different capacity of Soap Production Finishing Line

Toilet Soap Production Line: 100/200/300/500/800/1000kg/h

Laundry soap production line:100/200/300/500/800/1000/1500/2000kg/h

Features of Soap Production Finishing Line :

1. The finishing lines of Series for Laundry or toilet and translucent soap bring together all components that are most reliable, most durable, supplied by the most famous vendors in the world.

2. The mechanical design is tend to be simplified, more robust, low energy consumption, low off-stream rate, easy to be maintained ,more people oriented and with good view both outside and inside of the machines.

Machine parameter of Soap Production Finishing Line

Clients's Soap Production Finishing Line For Sale(For you reference):

Customized made toilet and laundrysoap bars for reference:

Packing and shipping of Soap Production Finishing Line

2, During the life-span of our machines, we should give consistent technique support and service, and we are pleasure to be on service of you.(24hours on line)

Name: jennyguo

Mobile:+86 156 1765 1038

Tel:+86 156 1765 1038

Whatsapp:+86 15617651038

Email:info@cnyomier.com

Add:No 2001, Building 2, No. 266,Songshan South Road,27District,Zhengzhou, China